Tayada ugu Wanaagsan ee Ferro Silicon ee Kaabista

isticmaal

(1) Qaybaha Silicon Ferro kaliya looma isticmaali karo warshadaha birta samaynta laakiin sidoo kale sida walxaha birta ah ee sida caadiga ah loo isticmaalo warshadaha birta ee kabka ah. Tani waa inta badan sababtoo ah walxaha silikoon ee ferro waxaa isticmaali kara warshadeeyayaasha birta ah si ay u beddelaan inoculants iyo spheroidizers. Warshadaha birta ah ee birta ah, qiimaha walxaha silikoon ee ferro aad ayuu uga hooseeyaa kan birta oo si fudud ayaa loo dhalaalinayaa, taasoo ka dhigaysa alaab tayo sare leh oo kabka birta ah. Inoculant qayb ka mid ah ferro Silicon tayo sare leh oo leh cabbirka qayb ka mid ah iyo saamaynta tallaalka wanaagsan inta lagu jiro tuurista waxay kor u qaadi kartaa roobka graphite iyo spheroidization, taasoo ka dhigaysa walxo macdan lagama maarmaan u ah soo saarista birta ductile.

(2) Loo isticmaalo sidii deoxidizer iyo wakiilka alloying ee warshadaha birta samaynta. Xidhiidhka kiimikaad ee u dhexeeya silikoon iyo ogsijiin waa mid aad u weyn, sidaas darteed qaybaha silikoon ee ferro ayaa ah deoxidizers xooggan ee birta samaynta roobka iyo deoxidation baahinta. Warshadaha samaynta birta, waxaa badanaa loo isticmaalaa sida wakiilka kuleylka koofiyadda si loo hagaajiyo tayada iyo soo kabashada ingot iyadoo la adeegsanayo sifada in miraha ferrosilicon ay sii deyn karaan kulayl badan oo ka soo baxa ene ee gubanaya heerkulka sare.

Walxaha Ferro Silicon ee wax soo saarka birta aan lahayn

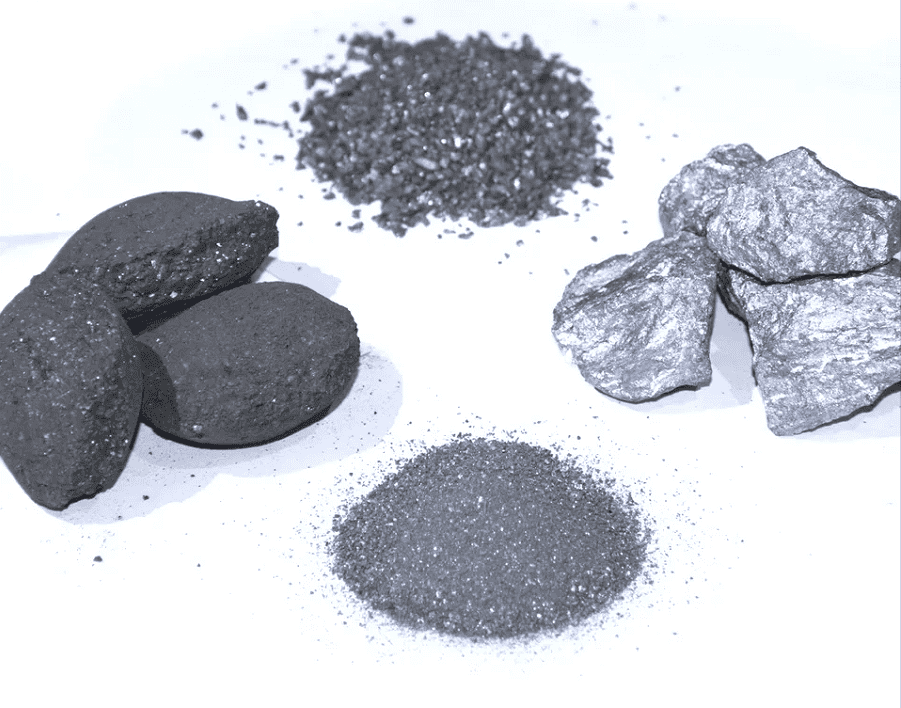

1. Qiimo jaban oo si fudud loo dhalaali karo

Qaybaha silikoon ee ferro ma aha oo kaliya loo isticmaali karo warshadaha birta, laakiin sidoo kale warshadaha birta ah ayaa inta badan loo isticmaalaa qalabka birta, inta badan sababtoo ah qaybaha silikoon ee ferro waxaa loo isticmaali karaa soosaarayaasha birta ah halkii ay ka isticmaali lahaayeen inoculants iyo nodulators, warshadaha birta ee kabka, qiimaha Qaybaha silikon ee ferro aad ayuu uga hooseeyaa birta, oo si fudud u dhalaalaysa, waa badeeco ferroalloy ah oo leh awood shubid.

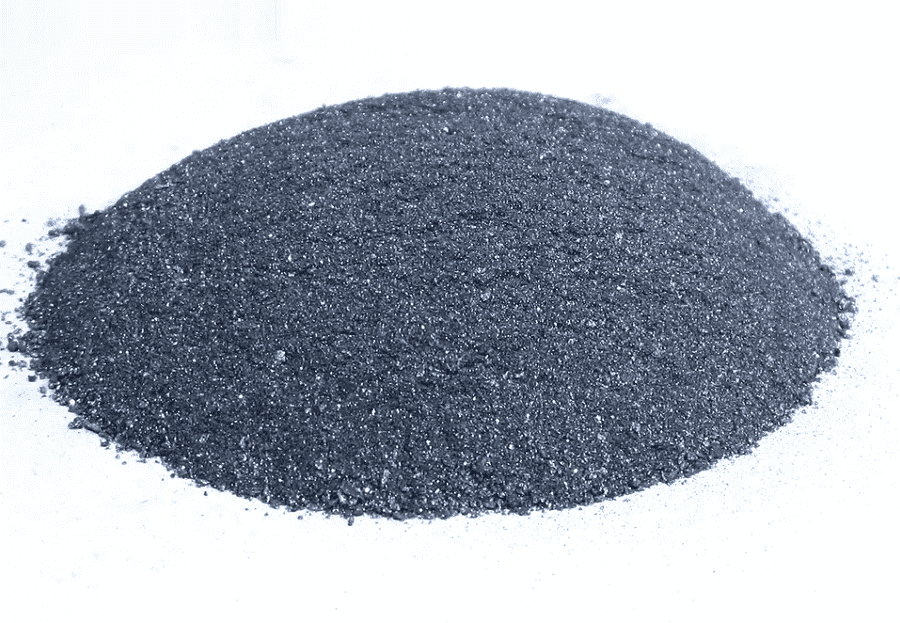

2. Cabbirka walxaha lebbiska ah

Qaybaha Ferro Silicon ma laha budo fiican, saameyn tallaal oo xasilan, iyo u janjeera yar oo ah inay soo saaraan dharbaaxo. Midda ugu culus ayaa ah inay leeyihiin astaamaha tallaalada kale oo ay leeyihiin kharash yar.

3. Barti wanaagsan iyo caag

Balaasti hooseeyaa waxa sabab u ah wax qabadkeeda foorarsiga oo hooseeya, xooggeeduna waxa uu dhowr jeer ka badan yahay tan qalabka birta fudud ee caadiga ah. Qaybaha silikoon ee ferro waxa kale oo uu leeyahay iska caabin daxalka aad u fiican, iyo lakabkeeda daahan ilaalinta ayaa si wax ku ool ah uga hortagi kara daxalka dusha sare ee shubka.

4. Mashiinka wanaagsan

Qaybaha Silicon Ferro waxay leeyihiin sifooyin farsamaysan oo wanaagsan, si dhakhso ah ayey u dhamaystiri karaan hawlaha habaynta adag, waxayna leeyihiin xasillooni wanaagsan oo xidhaan caabbinta, iyo sidoo kale nolol adeeg oo dheer. Taasi waa in la yiraahdo, qaybaha silikoon ee ferro waxay leeyihiin sifooyin farsamo oo wanaagsan iyo ku dhawaad eber guryaha haraaga ah, taas oo ka dhigaysa qalabka wax lagu shubo ee ugu fiican warshadaha shubka.

5. Guryaha heerkulbeegga heer sare ah

Qaybaha Silicon ee Ferro waxay leeyihiin sifooyin heerkulbeeg heer sare ah, waxay iska caabin karaan qallafsanaanta xaaladaha heerkulka sare ee kala duwan, waxayna ku ilaalin karaan xooggooda heerkul sare, iyaga oo si gaar ah ugu habboon isticmaalka soo saarista heerkulbeegga.

Curiyaha kiimikaad

| Shayga% | Si | P | S | C | AI |

| ≤ | |||||

| FeSi75 | 75 | 0.03 | 0.02 | 0.15 | 1 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.15 | 0.5 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.1 | 0.1 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.05 | 0.05 |

| FeSi75 | 75 | 0.03 | 0.02 | 0.02 | 0.02 |

| FeSi72 | 72 | 0.03 | 0.02 | 0.15 | 1 |

| FeSi72 | 72 | 0.03 | 0.02 | 0.15 | 0.5 |

Ogeysiis: Soo saarista tilmaamo kala duwan oo ah daawaynta kaalshiyamka silikoon iyadoo loo eegayo shuruudaha macaamiisha